- Home

- Aluminum Products

- Tubular Heater

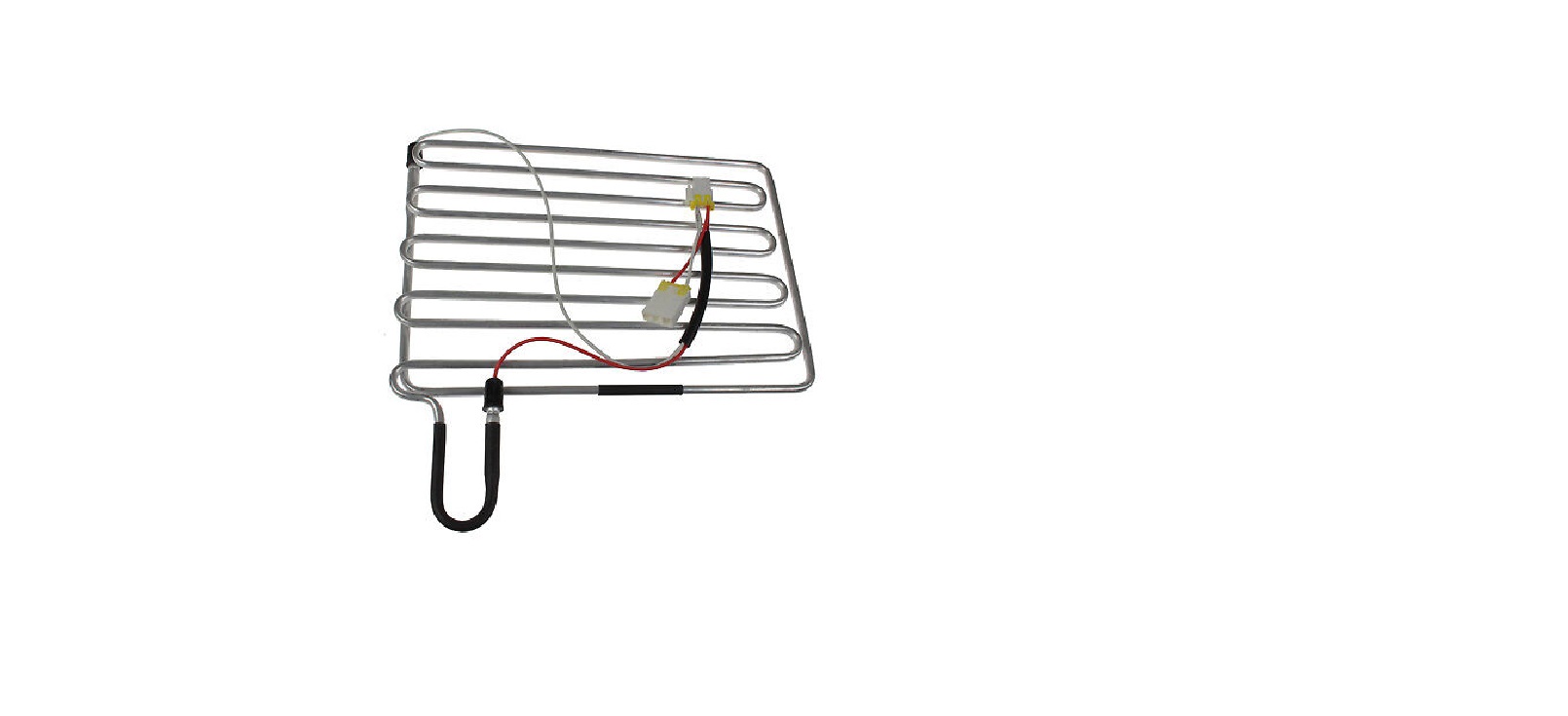

- Stainless Steel Heating Tube GS10100076

Stainless Steel Heating Tube GS10100076

The stainless-steel electric heating tube is sheathed with stainless steel, filled with magnesium oxide powder, and made of nickel-chromium wire as the heating wire. Divided into single head electric heating tube and double head electric heating tube. Among the factors affecting the quality of stainless-steel electric heating tubes, the quality of materials is an important reason. Reasonable selection of raw materials for electric heating tubes are the premise to ensure the quality of electric heating tubes.

SUS301 material, when deformed during processing, hardens, and is used in various high-strength applications.

SUS304 material is widely used in heating liquids (no strong acid and alkali) and air heating. It has good comprehensive performance, easy moulding and moderate price, and is most used in the manufacture of heating tubes.

SUS303 material, because it contains sulfur, is easy to cut. It is mainly used for convenient cutting and high requirements on stainless-steel surface finish.

Compared with stainless-steel 304, SUS304L has a lower carbon content, and the low-carbon stainless-steel has less carbides decomposed by thermal influence near the weld during welding, so the carbon emission is minimized, because carbides will cause welding corrosion.

SUS305 has a higher nickel content and is easier to form because of its lower work hardening rate.

SUS316 and SUS317 materials contain aluminum, which will be used in weak acid and alkali, and the acid and alkali resistance type is better than SUS304 material.

SUS321 material contains high titanium content and is generally used for high temperature welding and acid-base corrosion.

1. Material requirements:heating wire material; medium and high temperature magnesium powder;

2. Cold withstand voltage: 1500V/0.5mA/3s. Leakage current: 1.15 times the rated power and must not exceed 0.5mA;

3. The leakage current at the working temperature shall not exceed 0.5mA, and the voltage of the heating tube shall be adjusted to make the input power equal to 1.15 times the maximum rated input power under the condition of sufficient heat dissipation;

4. Overload test: the input power is 1.27 times the rated value, the heating tube is energized for 1 hour under the condition of sufficient heat release, and the power is off for 0.5 hours to room temperature ( forced cooling is allowed), which can withstand 30 cycles without damage;

5. Lifespan: The heating tube is connected to the rated voltage, energized for 1 hour under sufficient heat release conditions, and cooled down to room temperature for 0.5 hours after power off ( forced cooling is allowed), and the cumulative working time is >3000 hours;

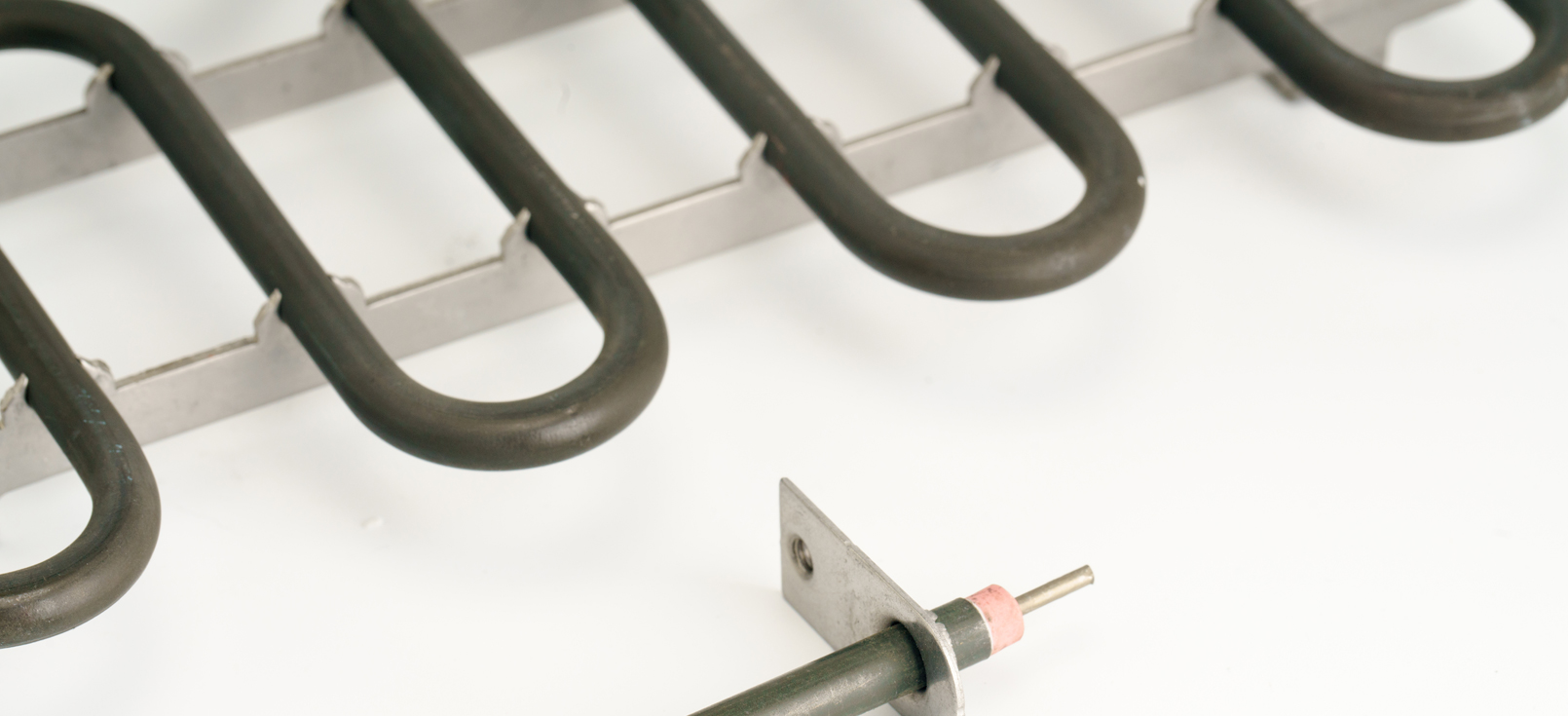

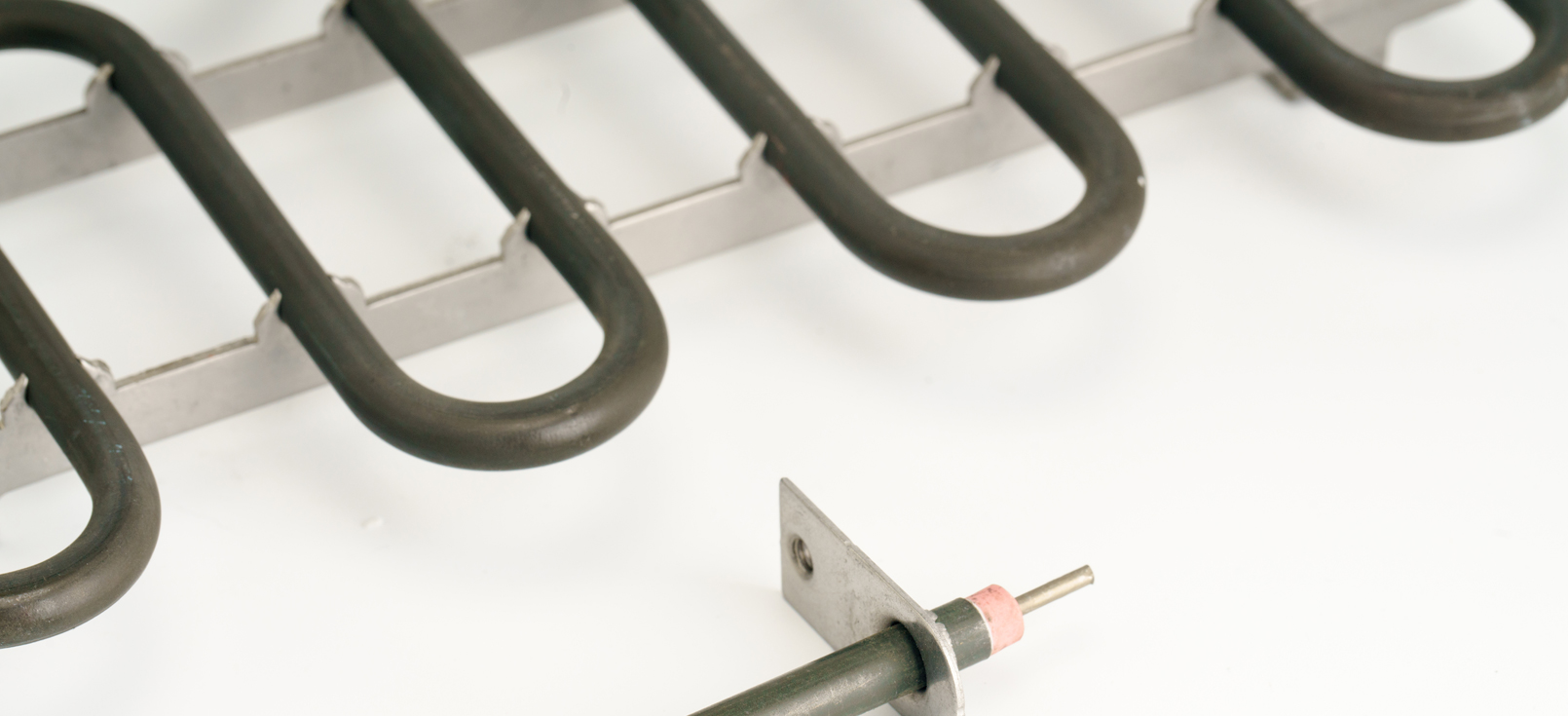

6. The surface of the tube body is black and oxidized, with uniform color, no scratches, bubbles, peeling or partial accumulation. The two ends of the lead-out rod are digging powder 5mm, which should be sealed with epoxy resin and silicone glue. Both ends of the ceramic sleeve package should be firm and reliable, and no loosening or air leakage is allowed;

7. Except for the cold end of the heating pipe, the heating should be uniform;

8. The final use state of the electric heating tube is flat, with a flatness of 0.5mm;

9. After the blade terminal and the heating tube lead-out rod are welded, they can withstand a tensile force of 10KG or a torsion force of 8KG;

10. All materials meet relevant certification requirements such as food hygiene;

- The terminals of the stainless-steel electric heating tube should be kept clean and dry, otherwise the insulation performance will be reduced and short-circuit breakdown will occur. Parts are fastened with insulating sealing devices to prevent accidents.

- The heating part of the stainless-steel electric heating tube should be completely immersed in the heating medium to avoid unpleasant heat dissipation and exceeding the allowable heating temperatures to damage the electric heating tube. In addition, the part of the wiring lead-out rod should be exposed on the insulation layer of the heater or outside the heater, so that this part should not be damaged by overheating.

- When the stainless-steel electric heating tube heats materials such as viscose, such as sodium nitrate, stearic acid, paraffin, etc., the power supply voltage should be reduced at the beginning of heating to reduce the calorific value of the electric heating tube. Increase the rated voltage for heating ( the voltage should not exceed 10% of the rated voltage marked on various electric heating tubes, if it is applicable to lower than the rated voltage, the heat generated by the electric heating tube will also decrease).

- The longer the stainless-steel electric heating tube is used, the thicker tube scale and oil scale are easy to accumulate on the surface, which should be removed regularly, otherwise the heat transfer performance of the electric heating tube will be reduced and the surface heat load of the electric heating tube will exceed the rated allowable and be damaged.

- Electric Boilers: electric water boilers, electric hot water boilers, electric heating boilers, electric bathing boilers, electric steam boilers

- Electric Ovens

- Chemical Equipment

- Plastic Molding and Auxiliary Equipment

- Hot-pressing Molding Machinery

- Cigarette Machinery

- Quick Sealing Machines

- Pharmaceuticals Machinery

- Sauna Equipment

- Electric Water Heater

- Kitchen Equipment

- Industrial Cleaning Euipment

- Commercial Air Conditioning and Drinking Water Equipment

- Solar Energy Equipment

- Electric Fryer Equipement

- Wave Soldering Electronic Automation Equipment

- Semiconductor Eutectic Welding

- Die Casting Input Channel Heating

- Plastic

- Food

- Medical

- Textile

- Petroleum

- Machinery

- Electroplating

- Packaging

- Other Industries

INQUIRY

CONTACT US

Foshan City Gaoming Gaosheng Alum Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us