Permanent Mold Casting

What is Permanent Mold Casting?

Permanent mold casting is the process of pouring molten metal into a mold to create new metal parts. These molds are usually made of metal (usually formed from gray cast iron, because it has the best thermal fatigue resistance) and can be reused, so they are called permanent molds.

Permanent mould casting can be divided into four main types: gravity, slush, low-pressure, and vacuum. The most common process uses gravity to fill the mold, but gas pressure or vacuum is also used. In addition, on the basis of the gravity casting process, also derived a process called slush casting, used to produce hollow castings.

Metals used in casting, commonly aluminum, magnesium, and copper alloys. Other materials including tin, zinc, lead alloys, iron and steel can also be cast in graphite molds.

The Advantages and Disadvantages of Permanent Mold Casting

The advantage of the permanent mold casting process is that the mold can be reused, greatly reducing material waste and improving production efficiency. At the same time, a highly automated casting process enables the production of metal pieces with more complex shapes at lower labor costs. The finished product has good surface finish and high dimensional accuracy. The rapid cooling caused by the use of metal molds allows the product to have a finer grain structure than sand casting.

Because of the high cost of creating metal molds, it is very uneconomical for small batch production. In addition, the mold is only suitable for non-ferrous metals, because of their low melting point, which can prolong the service life of the mold. If the permanent mold casting process is used for casting steel or iron, the mold life will be extremely short. At the same time, corrosion and thermal fatigue will reduce the service life of the mold. These are the disadvantages of this casting process.

Applications of Permanent Mold Casting

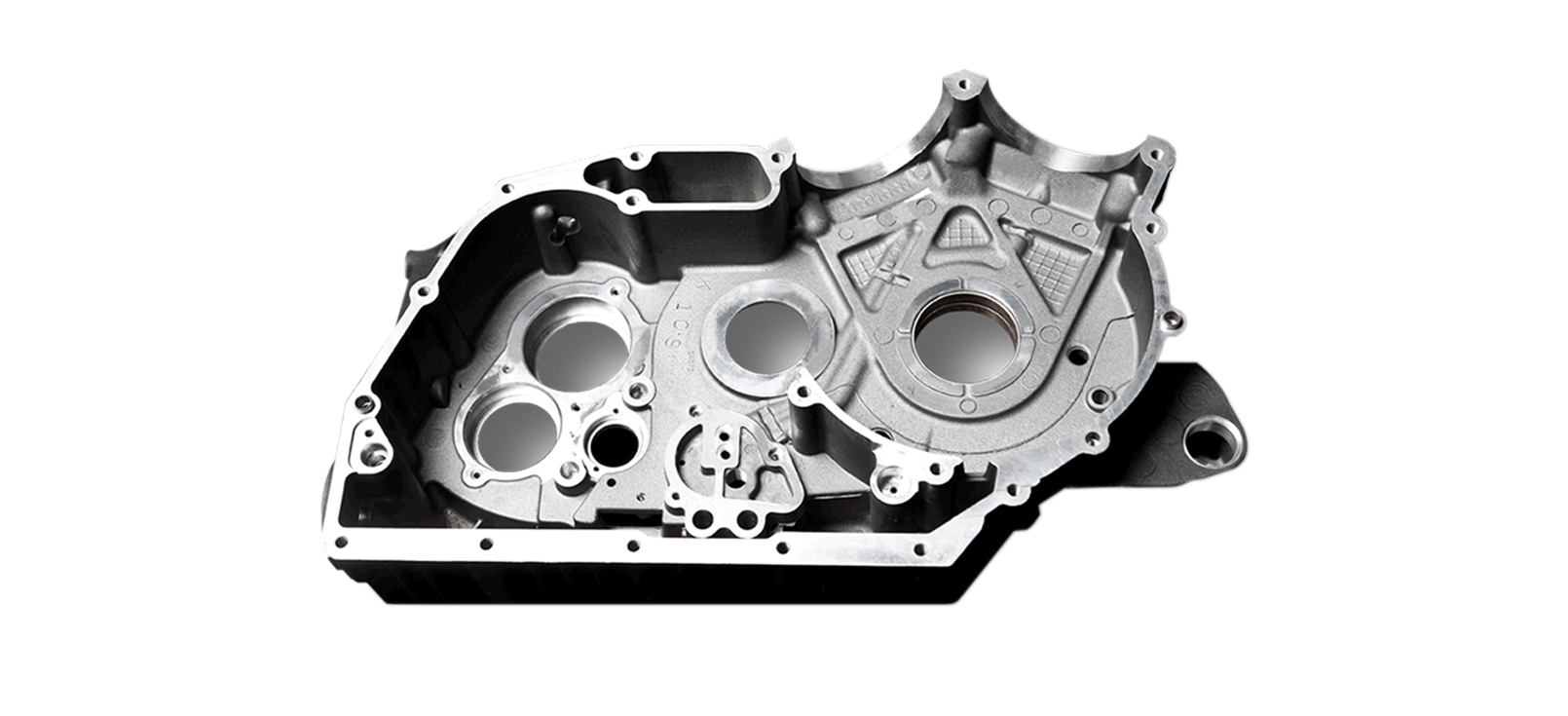

GSAL mainly provides gravity casting and low-pressure casting, our products can be used in industrial metal components, especially in the automotive industry, to manufacture parts such as gears, castings, suspensions, fuel injection housings and engine pistons. In addition, aircraft parts are often manufactured through the permanent mold casting process.

CONTACT US

Foshan City Gaoming Gaosheng Alum Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us