Magnet Wire

- By:

GSAL provides magnet wire with advanced equipment, high technology and reliable quality.

- Date:2024/07/27

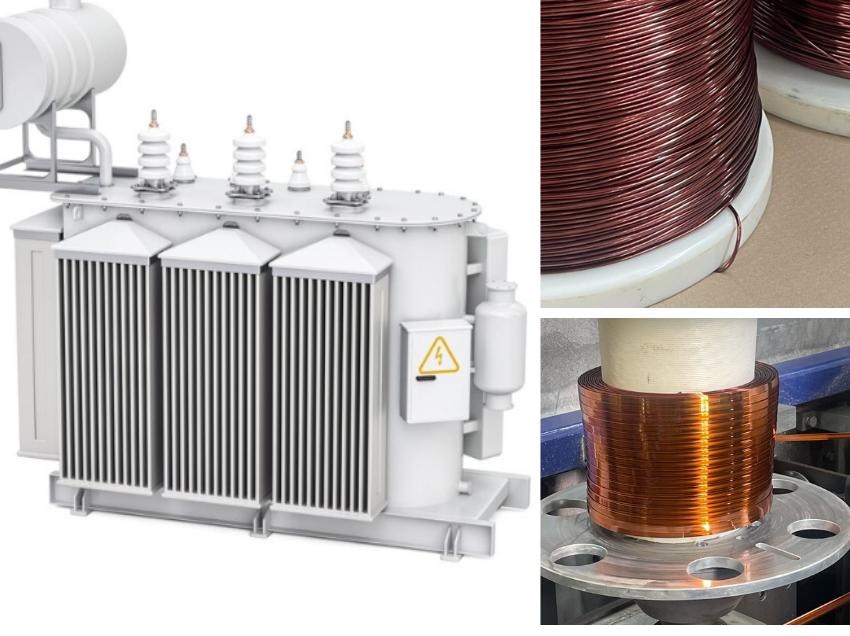

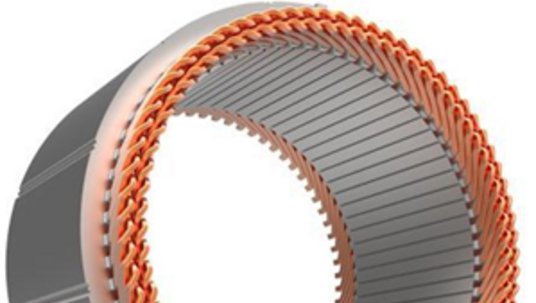

Magnet wire is a conductive metal wire with an insulating layer, such as polyester and polyesterimide, used to wind coils or windings of electrical products. Magnet wire uses the electromagnetic induction effect to generate a magnetic field through current to achieve the mutual conversion of electrical energy and magnetic field energy. It is an important component of electrical equipment, industrial and automotive motors, household appliances, power tools, instruments and etc.

Workshop & Equipment

GSAL has six production lines in total. There are 2 sets of round wires and 2 set of flat wire respectively. The other 2 sets of wires are for thick copper rods to thinner wires. The production capacity of flat wire and round wire is 800 tons and 1400 tons per month.

Enameled wire has four major properties: (a) Mechanical properties: good wear resistance, scratch resistance, and conductor has good flexibility and adhesion, the surface of the enameled wire is smooth and the friction coefficient is small; (b) Chemical properties: corrosion resistance, such as resistance to solvents, refrigerants, hydrolysis, pressure transformer oil, etc.; (c) Electrical properties: high electrical breakdown resistance; (d) Thermal properties: high temperature resistance from 155°C to 240°C (311°F to 464°F).

Overall, when selecting enameled wire, GSAL can help you comprehensively consider and carefully evaluate the performance of the material in a specific environment to ensure that the magnet wire achieves the best performance and reliability in the application.

|

|

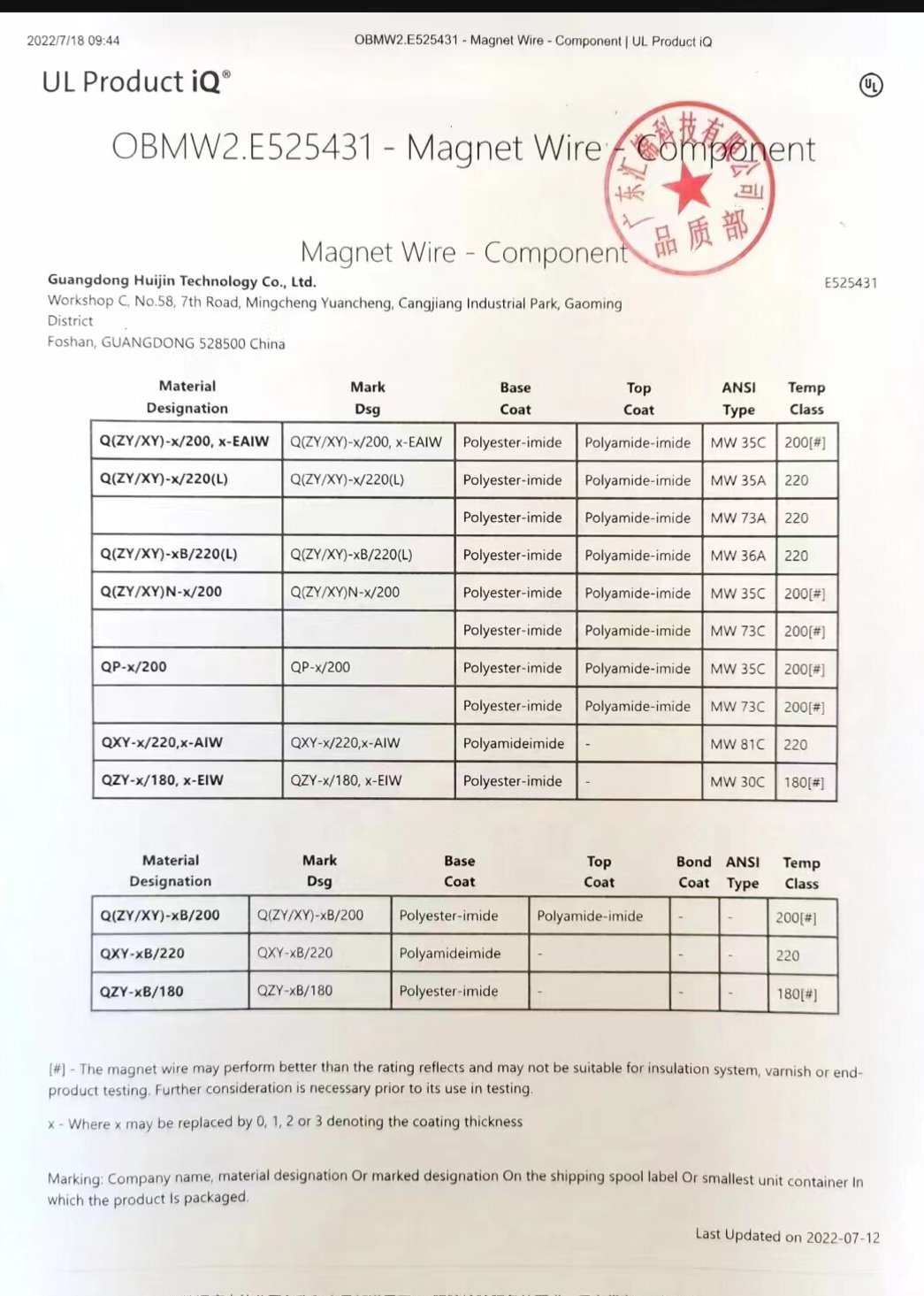

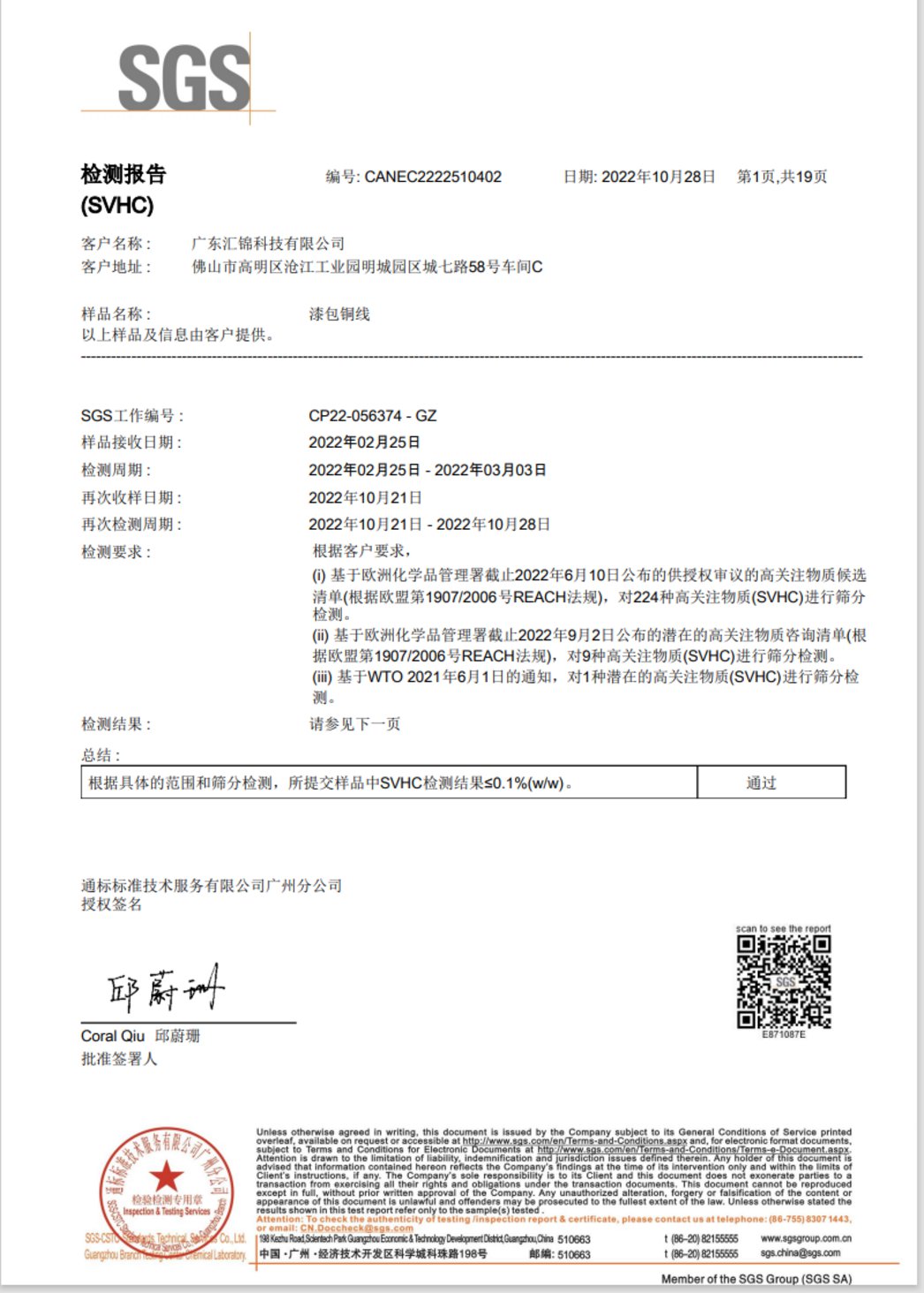

Certificate

|

|

|

|

|

| IATF 16949:2016 |

UL Certificate |

ISO 14001:2015 | ISO 45001:2018 | ROHS & REACH |

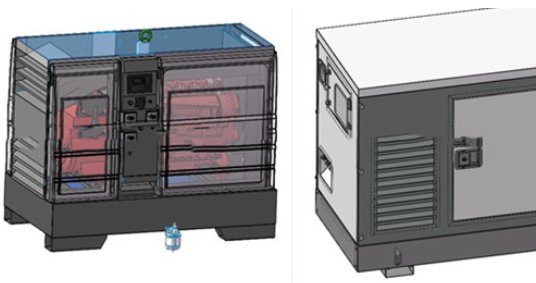

Application

Copper magnet wire has a wide range of uses, such as new energy vehicles, charging piles, high-speed rail, large wind turbines, frequency converters, motors, etc.

|

|

|

|

| Environmental-friendly Transportation | Charging Pile | Electrical Equipment |

Motor |

Cooperative Partner

|

|

|

|

|

|

|

|

CONTACT US

Foshan City Gaoming Gaosheng Alum Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us