- Home

- Aluminum Products

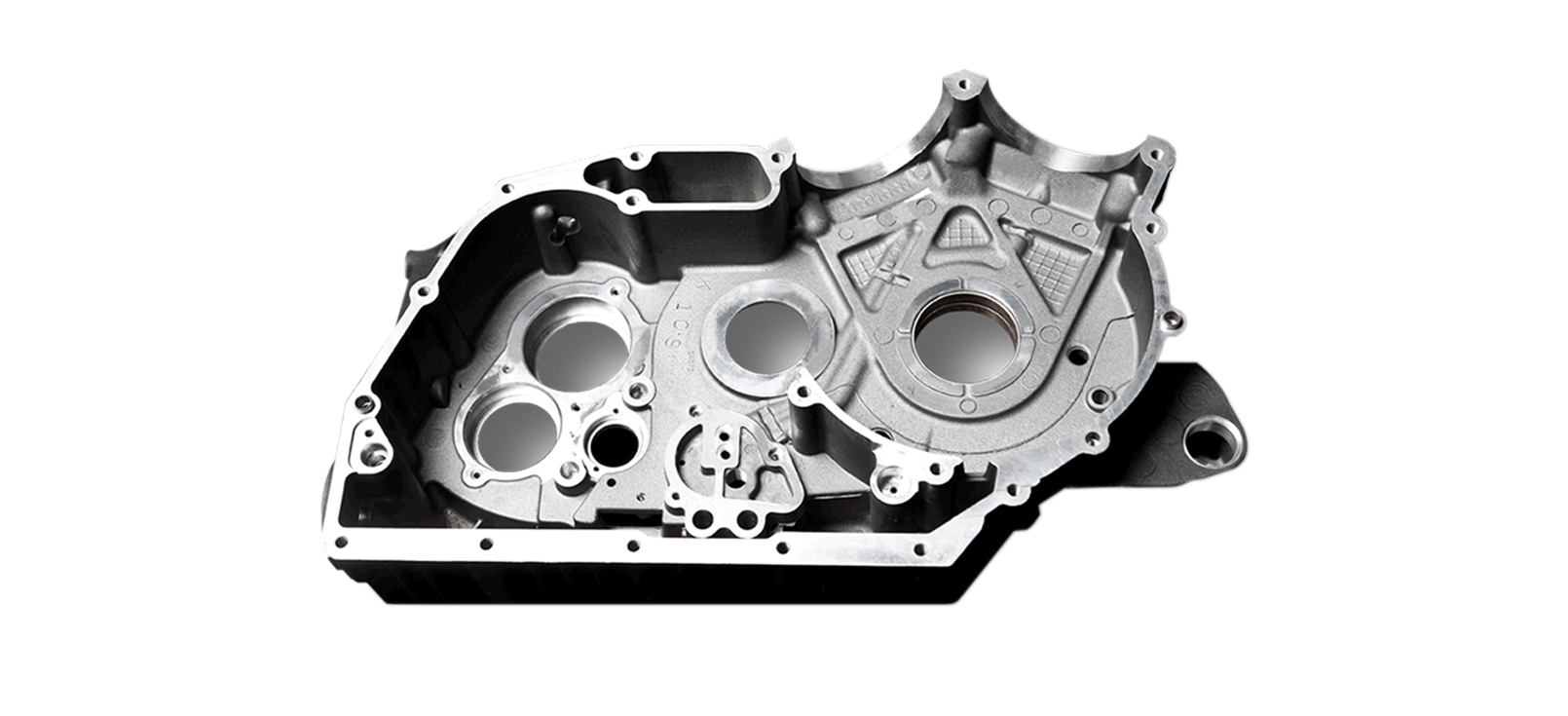

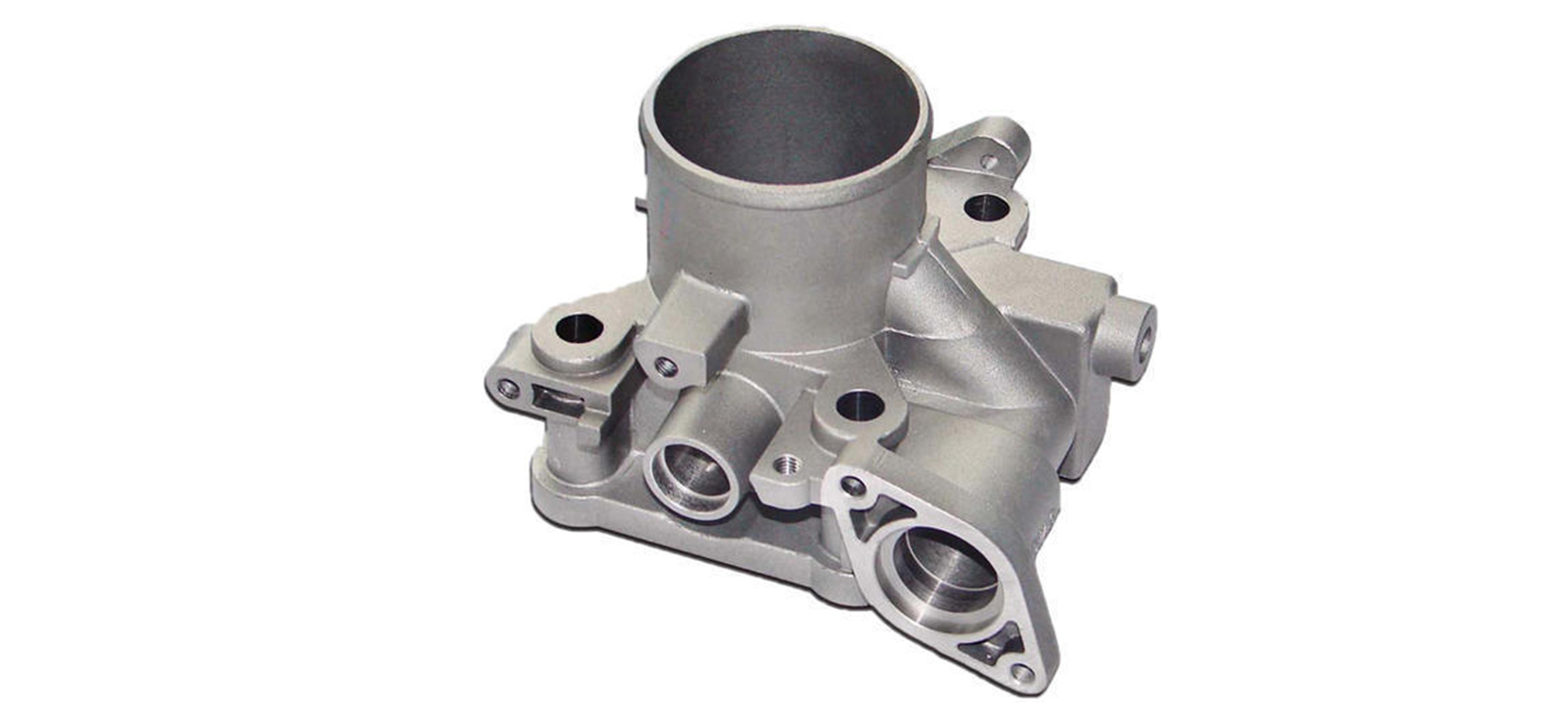

- Permanent Mold Casting

- Glavity Permanent Mold Casting

Glavity Permanent Mold Casting

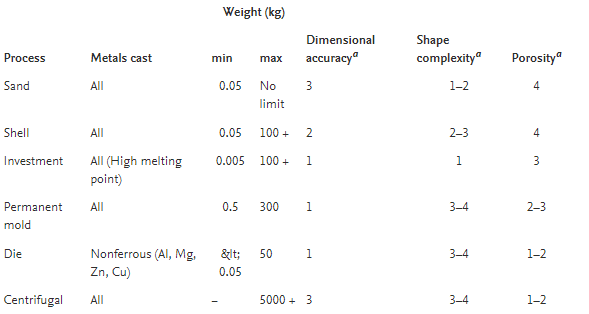

In permanent mold casting, molten metal is poured into a metal mold under the force of gravity, so it is often called gravity gravity mold casting. Currently,gravity casting is the most popular manufacturing process.

Metals that can be permanent mold casted is poured, either directly or by tilting the mold into a vertical position, into the mold in molten or liquid form without the use of pressure.

1. The heated mold is coated with a release agent. The release agent spray helps cool the mold face after the previous part is removed from the mold.

2. Pour molten metal into the channel in the device. Metal can be poured out not only by hand with a steel spoon, but also with a file. Typically, there is a "down runner" mold that allows the alloy to enter the mold cavity from the bottom of the mold, thereby reducing the subsequent formation of turbulence, pores, and inclusions in the finished part.

3. After the part has cooled sufficiently, manually or mechanically open the mold.

Aluminum casting products are widely used in the electronics industry, auto parts, motor parts, railway parts ship parts, medical equipment, ,aircraft parts,communication systems, other engine parts, etc.

INQUIRY

CONTACT US

Foshan City Gaoming Gaosheng Alum Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us