- Home

- Aluminum Products

- Permanent Mold Casting

- Low Pressure Permanent Mold Casting

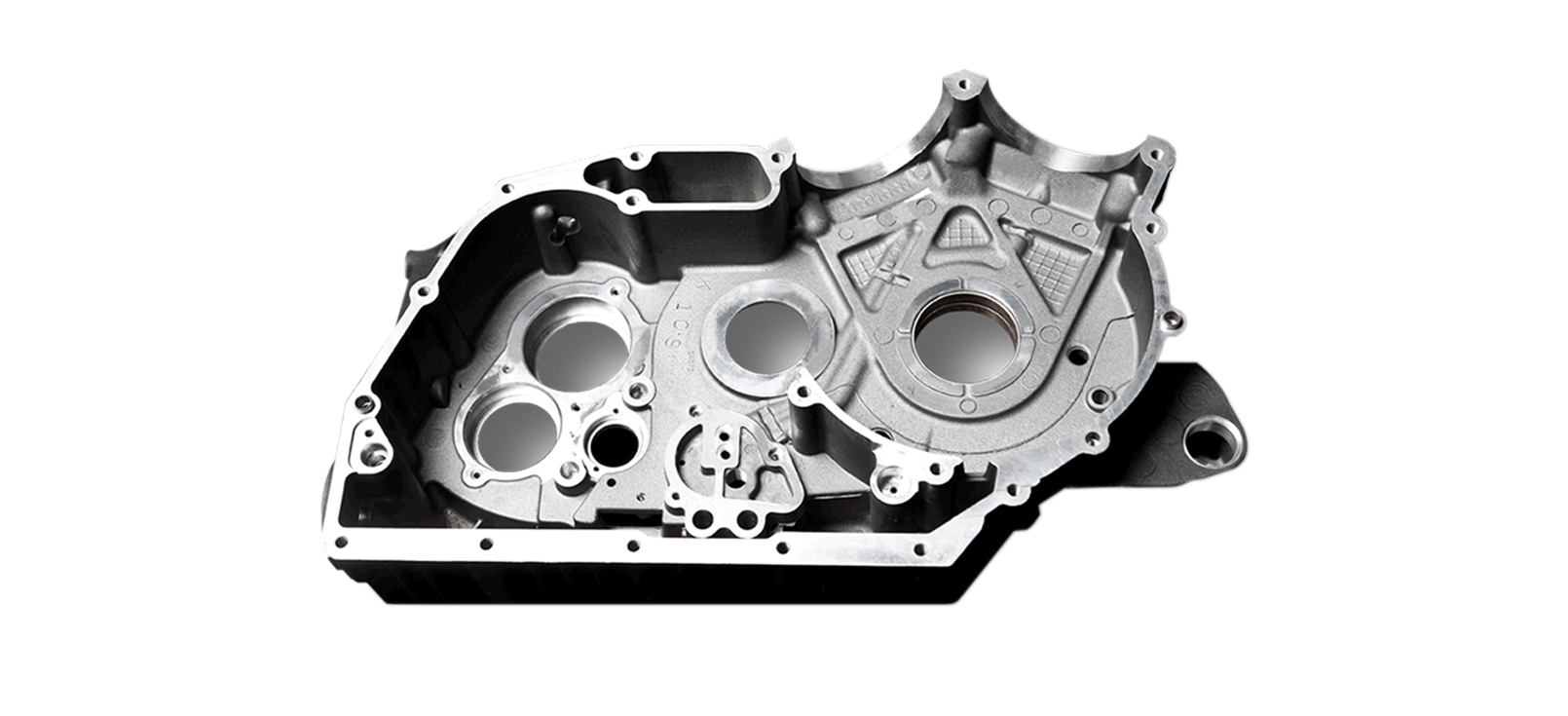

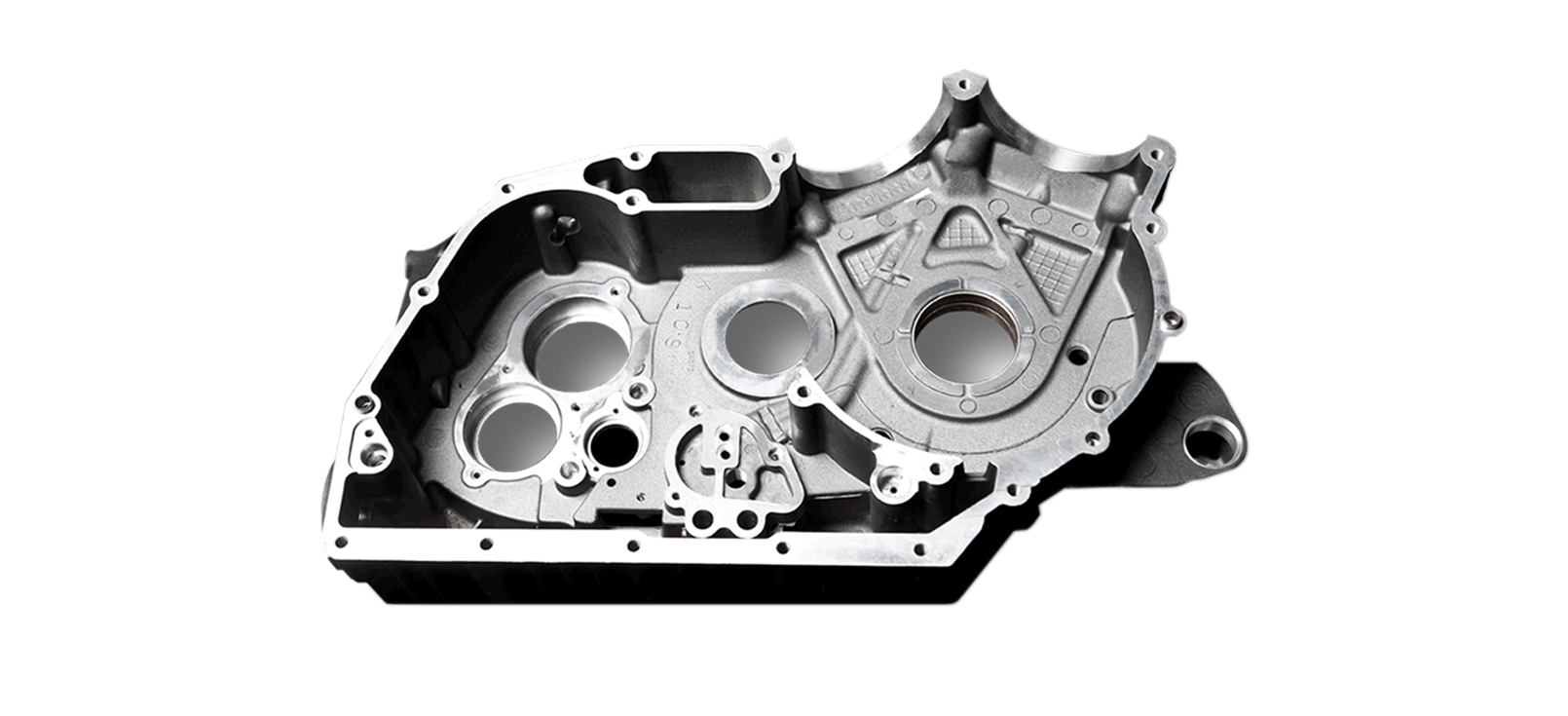

Low Pressure Permanent Mold Casting

The Low Pressure Permanent Mold (LPPM) manufacturing process is the cornerstone of GSAL. As a metal casting process, LPPM casting is the best choice for complex casting designs or castings that require structural and pressure tightness.

Low pressure permanent mold casting applies low pressure on a liquid aluminum reservoir, gently pressing the aluminum into the mold cavity. Pushing aluminum into the mold not only fills the cavity and contours of the casting shape, but it also increases the shrinkage of the casting during solidification. This achieves higher quality and more consistent castings while minimizing finishing operations and gate removal. Other benefits of low pressure die casting include improved mechanical properties and performance of the casting.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INQUIRY

CONTACT US

Foshan City Gaoming Gaosheng Alum Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us