Naturally, Casting molds are divided into permanent molds and disposable molds. The former can be repeatedly used for the manufacture of casting molds, while the latter, disposable molds, such as wood material molds remain in the casting mold and are destroyed by liquid metal during the casting process. Permanent mold casting includes pressure casting, metallic casting, centrifugal casting, and continuous casting. The casting of melting aluminum alloy products belongs to metallicity and pressure casting.

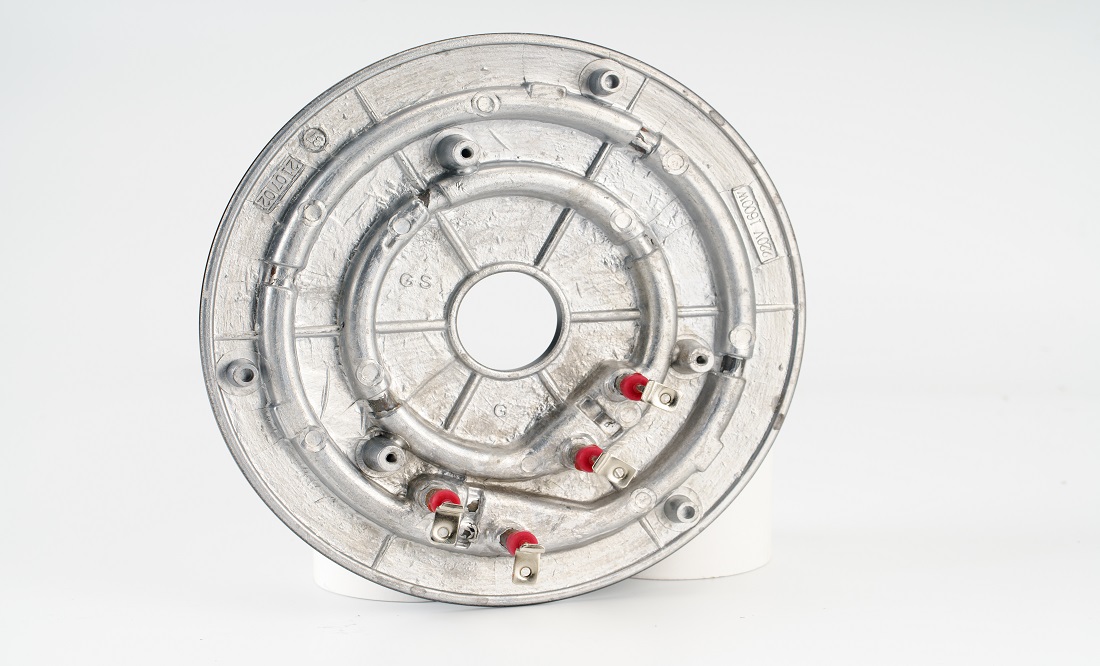

The heating plate produced by Gaosheng uses metallic and low-pressure casting technology. Gaosheng adopts high-precision machining of mold steel for the permanent molds can produce high-precision products, this is better to improve production efficiency and pass rate . The mold steel has the characteristics of fast heating, good heat preservation, weary resistance and pressure resistance. Moreover, what the most important is that it can be produced repeatedly to save production costs and achieve environmentally friendly recycling.

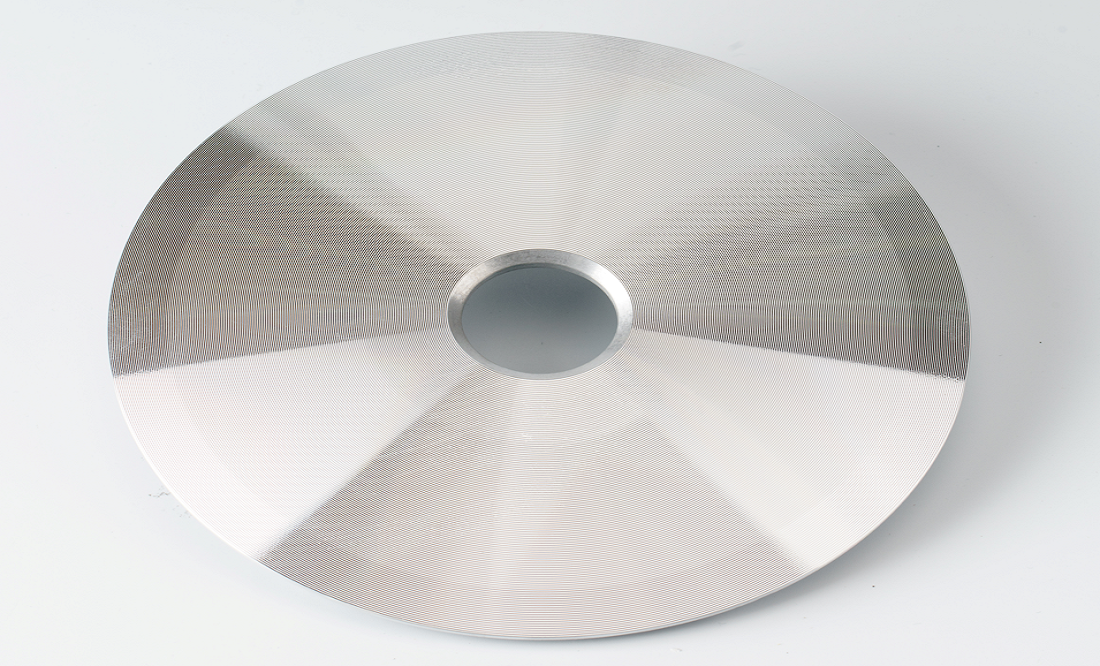

The permanent mold of the aluminum heating plate has three holes, one is the liquid metal inflow hole, and the other two are risers (in terms of technical terms). When the liquid metal solution fills the mold, the air in the mold escapes through the riser, thereby balancing the shrinkage of the liquid in the mold and avoiding the generation of shrinkage cavities (air holes). For example, the mold for producing the heating plate is a permanent mold. When the metal liquid flows into the mold, the liquid rapidly cools and shrinks, and bubbles will flow out with the two risers of the mold. The degree of outflow of the molten metal bubbles affects the uniformity and color quality of the heating plate surface. The more bubbles flow out, the better the uniform silver stripes can be processed by the heating plate, so the heating effect can reach the extreme. On the contrary, the stripes of the aluminum plate are uneven, which affects the properties of the product. Disposable molds cannot be used for the production of heating plates, because disposable mold materials, such as wood and sand materials, have low casting strength and high melting point, and the finished product effect is not ideal, especially the surface quality.

In a nutshell, Permanent molds are the best choice for manufacturing heating plate products because they can be cycled production and are beneficial to production efficiency. The most important thing is that the mold has a low melting point and fast fluidity, and the product has a uniform shape and surface and good quality. When you are planning to purchase the heating plate, the best way is to choose an reliable electric industrial heater supplier for the safe opeation in the daily life like our Gaosheng Company.

CONTACT US

Foshan City Gaoming Gaosheng Alum Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us