Part One # What Are Stainless Steel Heating Elements ?

When it comes to stainless steel heating elements, you'll want to be careful about the material you choose. Stainless steel is an extremely hard material and you may want to choose an alloy that won't rust. You'll also want to avoid using a magnesium anode in the heating element, which can cause corrosion. Stainless steel is slightly darker than other materials, so you'll have to be extra careful when choosing one.

The base of a stainless steel heating element is usually made from 304 grade stainless steel and will not rust. The grey/charcoal heating rods are made of the highest grades of nickel and chromium. A good stainless steel heating element will be made of 804 grade, which is high temperature and corrosion resistant. It's also more expensive than standard 304/316 grade, but is much stronger and will never rust. Stainless steel is relatively flexible. You can bend them if you need to. Some elements come pre-bent, but you should still look for one with a limited warranty. You should also take a look at the bending radius of the stainless steel heating element. You should make sure it's suitable for the bending shape you need. Otherwise, you might end up with a heater that rusts. Then again, you can always replace it.

The stainless steel heating element should be made of 304 grade. It should be durable and resistant to rust. It should also be flexible enough to bend. If you're a beginner, you should choose a high quality stainless steel heating element. The higher the quality, the more durability you'll have. The material itself is also easy to clean, and will withstand the heat of a liquid. So, make sure you read the instructions before you buy a stainless steel heating system. The 304 grade stainless steel heating element is a good choice for most types of kettles. It is 1.25" in diameter and can heat up to 10 gallons of water in one and a half hours. The heating element must be plugged into an appropriate thermostat and preferably be submerged in water. It should not be exposed to any type of moisture, including rainwater, as it will affect the efficiency of the heating device.

Stainless steel is a very hard material and you need to be very careful when choosing one. The 304 grade heating element should not be left in a dry state and should be completely submerged in water. The heater should be kept away from rust and water as it could cause serious damage. If it's left in a dry state, it will rust and might cause your wort to foam. You should also keep in mind that a 316 grade heating element will last longer than a 304 grade one. While stainless steel is an extremely hard material, it is flexible and should be used with care. You should pay special attention to the bending radius of the steel heater, because this will determine whether it will be safe to use. The bending radius of a 304 grade heating element is 1.4 inches, and it can be used to heat 10 gallons of water in 1 and a half hours. However, you should make sure that the heater is completely submerged in water and that it doesn't come with a dry element.

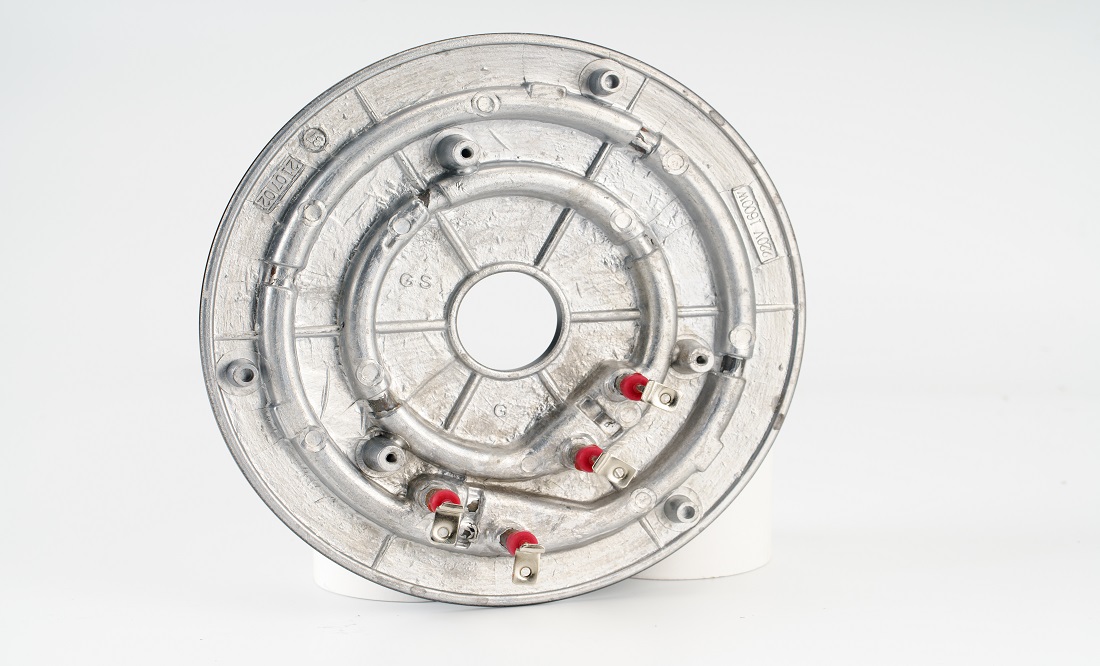

Part Two # Introduction For Process of Aluminium Casting

The process of aluminum casting involves the addition of various elements to the aluminium bath. Hardeners such as silicon, iron, copper, magnesium, chromium, and zinc are added to the metal bath to give it a stronger and harder structure. These elements are added to the casting bath to reduce grain size and improve extrusion properties. This process is known as die casting. This process is a complex one, but the end result is an aluminum product that is highly durable and corrosion resistant.

Various types of equipment are available for aluminum casting. These machines use different methods to create unique objects. The process itself is complex, and there is no single technique that will produce the best results. Some producers specialize in a specific method, but most manufacturers offer customers the choice of processes. They will then choose the one that is best for their products. This process is very time-consuming and requires special skills.

The most common alloy for aluminum is 8000 series. This series is composed of tin and copper with small amounts of nickel. It is relatively strong, and has low tendency to hot crack. The 8000 series has excellent machinability and wear resistance. Because of its low melting point and other properties, it is a popular choice for many industries. these alloys also have a longer lifespan. This is one of the main reasons why aluminum castings are widely used in the aerospace industry. In fact, cast aluminum components make up 80 percent of the aircraft's structure.

The process of aluminum casting is important for many reasons. It is a versatile material, which is used in everything from construction to aerospace and automobile components. A good alloy is highly resistant to corrosion, and it is easy to weld. It also resists heat. It is the preferred material for the construction of aircraft. Its mechanical properties are incredibly strong and can last for a very long time. These components are vital to many industries, so it's important to choose the right alloy for your project.

As the aluminum alloy is so popular, it has many applications. It has a great range of properties, including high tensile strength and corrosion resistance. Its lightweight, corrosion-resistant, and thermal-conductive properties make it ideal for a variety of applications. Its primary end-use is the transportation industry. The increasing popularity of vehicles has spurred the development of the aluminum casting industry. This is due to a variety of factors, such as the increasing emission laws and consumer demand.

The advantages of aluminum casting are numerous. It has an outstanding strength-to-weight ratio, and is lightweight and corrosion-resistant. Its attractive aesthetic value makes it a desirable material for many industrial applications. The benefits of aluminum castings are countless.

CONTACT US

Foshan City Gaoming Gaosheng Alum Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us